Key points:

·The tensile strength and tensile modulus of carbon fiber composite are about 50% higher than that of T300;

·Glass fiber composites can meet the design requirements of low dielectric constant and reduce manufacturing costs;

·Fluorine plastic parts can help large aircraft high temperature and corrosion resistance;

·Aramid honeycomb material can achieve light weight and high strength;

·For the first time, aromatic sulfone fiber was used in the interior of the C919 cabin to make seat covers and door curtains, which reduced the weight of the aircraft by more than 30 kilograms.

The first commercial flight of China’s large aircraft C919 has been successful. From Shanghai to Beijing, from Shanghai to Chengdu, the smooth landing again and again means that domestic large aircraft officially entered the civil aviation market, opening a new journey of market-oriented operation and industrial development!

The C919 successfully completed its first commercial flight. (Photo credit: people.com.cn)

Large passenger aircraft are arguably the most complex and technologically sophisticated products in the world today. As one of the important materials to help large aircraft achieve lightweight, flame retardant, high temperature and corrosion resistance, which parts of the C 919 show their skills this time?

1. T800 grade carbon fiber composite material

At present, the C919 rear fuselage rear section, flat tail, vertical tail, elevator, rudder, flaps, ailerons, winglets, spoiler and other parts are using carbon fiber composite materials.

The carbon fiber composite material used is mainly T800 grade. It adopts toughened epoxy resin matrix, reinforced fiber is T800 carbon fiber, tensile strength and tensile modulus is about 50% higher than T300, and is also the most widely used composite material in the international civil aircraft main bearing structure.

2.glass fiber composite materials

Compared with carbon fiber composites, the mechanical properties of glass fiber composites are slightly lower, but because of the high dielectric constant of carbon fiber, it will affect the radar work, and the radome of C919 large passenger aircraft uses glass fiber composites.

Other parts with less stress, such as flaps, also use fiberglass composites. Because the cost of glass fiber composite materials is lower than that of carbon fiber composite materials, the application of small force components can both meet the design requirements and reduce the cost.

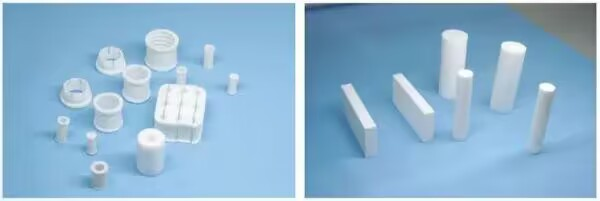

3.fluorine plastic products

Fluorine plastic products provided by Gerui New material. (Photo from Gerui New Material)

Aviation fluoroplastic products as one of the non-metallic standard parts used in large aircraft, its raw material is polytetrafluoroethylene, that is, the legendary “plastic king”.

These standard parts produced by polytetrafluoroethylene have excellent properties such as high and low temperature resistance, corrosion resistance, electrical insulation, etc. The products are mainly used to fix and connect the complicated wires and cables and pipes on the aircraft.

Zhejiang Gerui New Materials Co., LTD. (referred to as “Gerui New Materials”) has delivered eight categories of products for the domestic large aircraft C919, and each C919 large aircraft uses more than 10,000 aviation fluoroplastic products.

4.aramid honeycomb material

The doors of the C919 large passenger aircraft and the floor of the passenger and cargo compartment are made of aramid honeycomb material, a lightweight, high-strength non-metallic bionic core material made of phenolic resin impregnated aramid paper. It mimics the honeycomb design of bees, has a stable, lightweight structure and high specific strength, it has higher shear strength compared to foam core material, and it is more resistant to corrosion compared to metal honeycomb.

At the same time, the aramid honeycomb material also has high toughness, good fatigue resistance and fire resistance, and is an ideal civil aircraft composite material.

5.Aromatic sulfone fiber

C919 cabin for the first time to use aromatic sulfone fiber to make chair cover, door curtain, will make the aircraft weight reduction of more than 30 kilograms, each aircraft can save more than 10,000 yuan cost.

Aromatic sulfone fiber is called PSA fiber, which is composed of polysulfone amide. Its main characteristics are excellent electrical insulation and heat resistance. In addition, high flame retardant, limiting oxygen index of more than 30%, good chemical stability. In addition to several highly polar solvents and concentrated sulfuric acid, it has good stability to chemicals at room temperature.

Aromatic sulfone fiber can not only make a variety of high temperature resistant filter materials and high temperature and high voltage electrical insulation materials, but also can be processed into advanced flame retardant fabrics in transport vehicles.

6.Rubber compound

Airplane tires are made of the same material as car tires, but the main difference is that airplane tires use a higher strength rubber compound, so that airplane tires can be inflated to 200 pounds per square inch of Air pressure, which is equivalent to six times the pressure of car tires, and the C919 uses Air X radial tires from Michelin.

YIHOO POLYMER is a global supplier of additives for the modification of plastics and coatings, including UV absorbers, antioxidants, light stabilizers and flame retardants, which have been widely used by customers in Europe, the United States and the Asia-Pacific region.

Enquiries are welcome at any time: yihoo@yihoopolymer.com

Post time: Jul-17-2023