Hydrogen, which can react with oxygen to form water, is an ideal secondary energy source. Among them, hydrogen produced by renewable energy sources such as solar and wind power is called green hydrogen. Green hydrogen has great development potential due to its zero carbon emission. Green hydrogen industry chain from hydrogen production, storage and transportation to hydrogen fuel cell applications is attracting much attention.

Therefore, this article specially collates the hydrogen-related products on display at Chinaplas recently. The main products are as follows:

●PPS is used in the diaphragm of alkaline hydrogen electrolytic cell and the end plate of fuel cell.

●PA is used in hydrogen storage bottles and hydrogen transmission lines;

●Proton exchange membrane, PTFE electrolytic cell seal gasket, etc.

Ⅰ.PPS:Diaphragm of alkaline hydrogen electrolytic cell and the end plate of fuel cell

1.ORIDA™AUSTON® PPS Hydrogen energy bipolar plate

Specification: B4300G9LW、B4200GT85LF

Features: Toughening, enhanced and high size stability, high temperature resistant, high barrier property and high liquidity.

2.National material: PPS end plate/deflector plate

Guocai (Suzhou) New Materials Technology Co., Ltd. is mainly engaged in the research and development, production and sales of high performance modified thermoplastic composites such as polyphenylene sulfide. This exhibit shows the PPS end plate/deflector, with hydrolysis resistance, low ion precipitation, corrosion resistance, dimensional stability, aging resistance and other characteristics.

Hydrogen fuel cell PPS end plate/deflector plate

3. Deyang Keji High-tech Materials : PPS hydrogen diaphragm

Deyang Keji High-tech Materials Co., Ltd. engaged in the research and development, modification and production of PPS, PEEK and other engineering plastics. The main products of the company are polyphenylene sulfide filament, special basalt cloth, modified PPS hydrogen production diaphragm, etc.

Ⅱ.PA is used in hydrogen storage bottles and hydrogen transmission lines

4. Evonik: PA12 hydrogen transport tube, gas separation membrane

The multi-layer hydrogen delivery tube made of Evonik polyamide 12(VESTAMID®) is lighter than conventional metal pipes, and the fluorine material inside is cleaner and protects against hydrogen embritzement.

VESTAMID®Hydrogen delivery pipe

The pipeline, made of VESTAMID®NRGPA12, will create a more cost-effective gas transmission and distribution network. The maximum working pressure of PA12 pipeline is 18Bar, which can replace the carbon steel pipeline in the gas transmission network. Due to the extremely low permeability coefficient of the PA12 pipeline, its safety has been certified by DVGW as H2 Ready, making it more suitable for hydrogen delivery related applications.

VESTAMID® NRG Natural gas/hydrogen lines

Evonik SEPURAN® brand stands for customized hollow fiber membranes designed for high efficiency gas separation. It can be used for separation and purification of methane, nitrogen, hydrogen and other gases. SEPURAN®Noble membranes selectively extract and recover high concentrations of hydrogen gas from natural gas pipelines transporting a mixture of methane and hydrogen gas.

SEPURAN®Gas separation membrane

5.Arkema: PA11 hydrogenation pipe and hydrogen storage tank liner

Arkma bio-based PA11 applied to hydrogenation pipe and high pressure hydrogen storage cylinder, has excellent hydrogen gas barrier, high pressure hydrogen bubbling resistance, high and low temperature resistance, environmental protection, excellent processing performance and other characteristics.

Hydrogenation pipe

Inner tank of high-pressure hydrogen storage bottle

6. Lotte Chemical: Hydrogen storage tank (PA lining +CF composite winding)

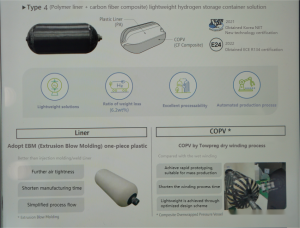

Lotte Chemical is working to become carbon neutral. In order to provide the optimal hydrogen storage solution, Lotte Chemical has developed the Type IV (Type 4) lightweight high-pressure hydrogen storage container and established the Pilot production line, which is laying the foundation for a variety of hydrogen mobility fields such as hydrogen electric vehicles (passenger vehicles/commercial vehicles), industrial machinery/construction machinery, and unmanned aerial vehicles.

In particular, the world’s highest weight loss ratio (6.2wt%) was achieved through the development of a one-piece liner that simplified the process and enhanced air tightness, and increased productivity through the development of a dry winding process and the optimization of winding lines.

Hydrogen storage tank (Type Ⅳ /700bar)(PA polymer liner +CF composite material), mass efficiency :6.2wt%, tractio winding → high productivityn

7.Basf: PA hydrogen storage cylinder liner rolling and fuel cell engine manifold

Basf Uitramid® PA for fuel cell vehicles, can be used as a type IV hydrogen storage tank to provide reliable permeability blocking ability, has excellent processing performance, with excellent low temperature toughness and strength; The roll-grade specification is suitable for the preparation of large volume hydrogen storage cylinders for commercial vehicles, while providing injection molding and blow molding material solutions.

Type IV hydrogen storage tanks for fuel cell vehicles and stationary stations

Laboratory grade liner roll sample

In addition to hydrogen storage cylinders, BASF also demonstrated the application of PA to fuel cell engine manifoles and thermal management system components with high efficiency, safety, reliability, hydrolytic resistance to coolant applications, precision injection molding structures, thin-walled and large-size structural components, etc.

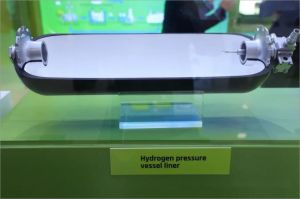

8. Korea Kolon: Lining of hydrogen storage bottle

Kolon Industries, one of South Korea’s larger nylon factories, also displayed a sample hydrogen storage bottle liner.

Lining of hydrogen storage tank

Ⅲ.Proton exchange membrane, electrolytic cell sealing gasket

9. Lin Wei, Jiangsu: PTFE alkaline electrolytic cell seal gasket

Jiangsu Linwei New Materials Co., Ltd. is a manufacturer of PTFE products. This time, there is a sample of PTFE alkaline electrolytic cell seal gasket on display.

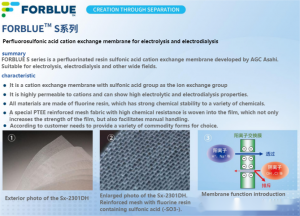

10. AGC: Fluorine resin ion exchange membrane

AGC’s fluorinated resin ion exchange membrane “Forblue S Series” is adopted for its high security, long life and large capacity.In the field of fuel cells, Forblue’s i series is widely used in fuel cell electrolyte membranes and electrodes due to its high endurance power generation performance.

Water electrolysis Forblue S series

YIHOO POLYMER is a global supplier of additives for the modification of plastics and coatings, including UV absorbers, antioxidants, light stabilizers and flame retardants, which have been widely used by customers in Europe, the United States and the Asia-Pacific region.

Enquiries are welcome at any time: yihoo@yihoopolymer.com

Post time: Jun-07-2023